The Evolution of Collaborative Logistics The package delivery landscape is undergoing a revolutionary transformation as businesses and logistics providers recognize the untapped potential of excess capacity utilization. Traditional delivery models, heavily reliant on...

Empowering Business Decisions with AI and Advanced Analytics

We build intelligent systems that anticipate, adapt, and optimize—grounded in real-world constraints and research-backed algorithms.

Innovative Analytics for Strategic Advantage

Experts and Cutting-Edge Research

Data-Driven Insights

Advanced Data Mining

Predictive Modeling, IoT, and Prescriptive Analytics

AI-Powered Decision Support

Continuous Innovation

Our Services

Prescriptive Analytics

We develop advanced AI-powered prescriptive solutions that predict trends and recommend optimal actions. Our tools empower businesses to make informed strategic decisions, optimize outcomes, and confidently tackle challenges. By leveraging insights, we drive data-driven strategies aligned with your goals and ensure success.

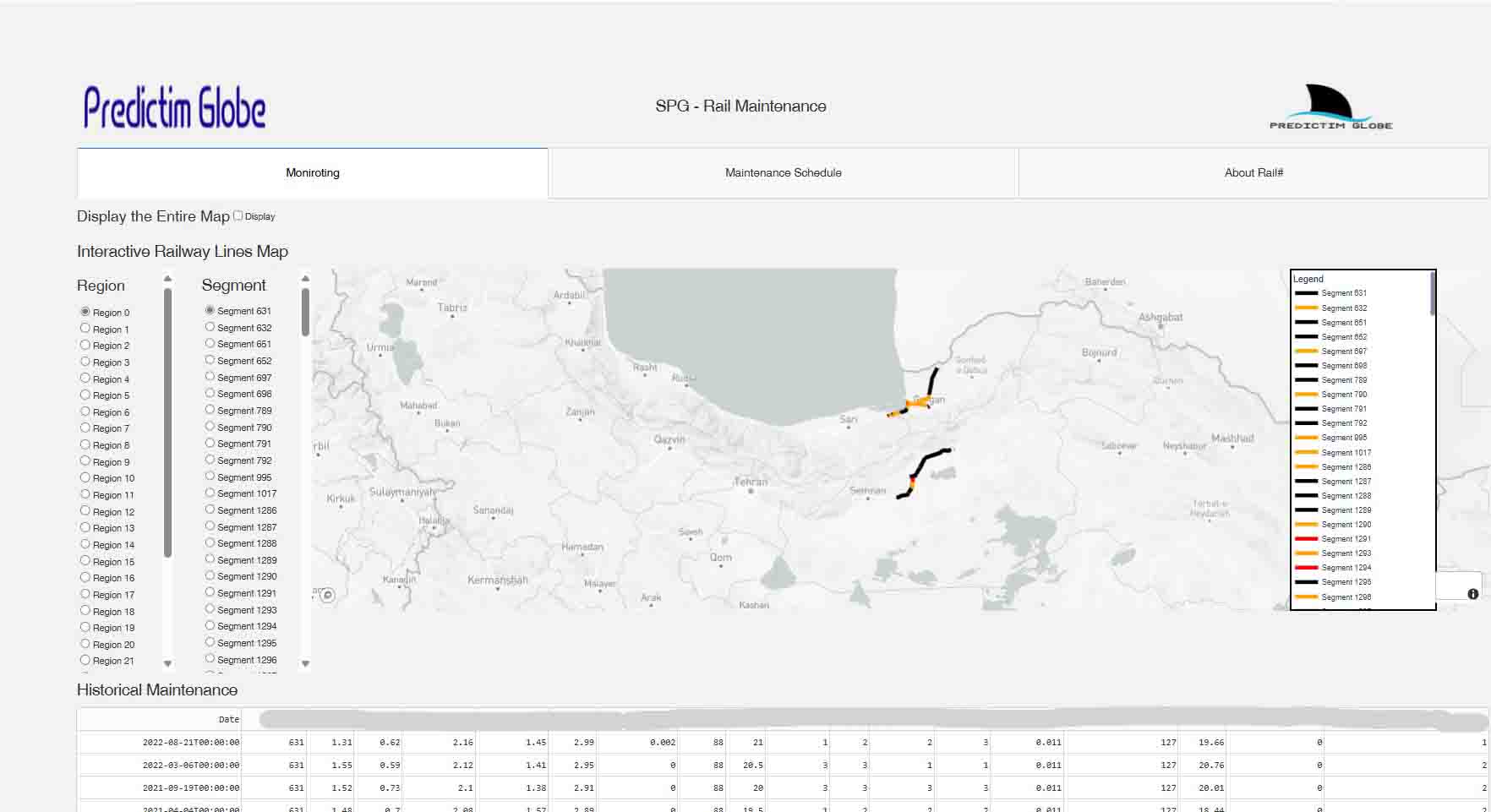

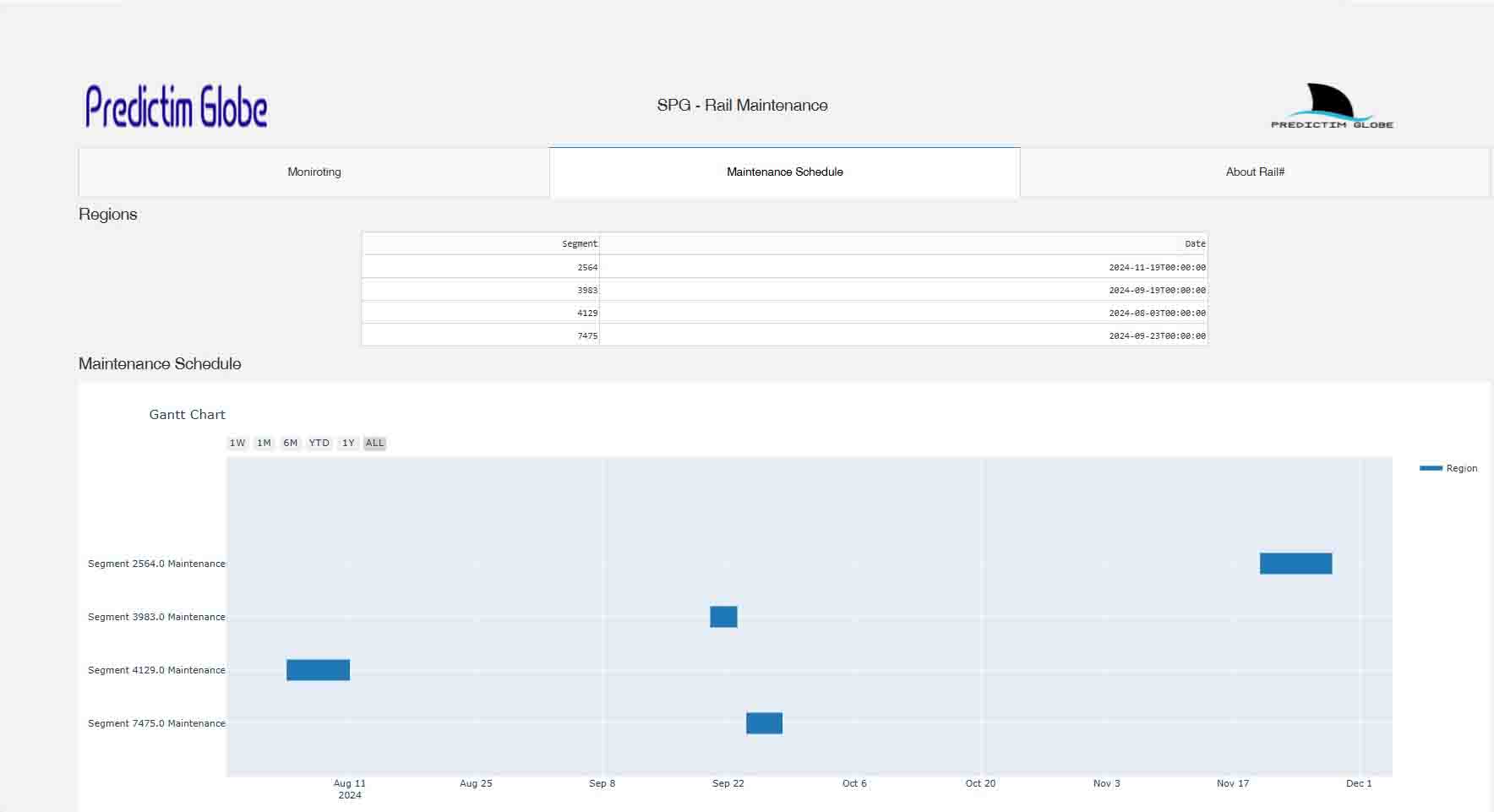

Railway Predictive Maintenance

Our advanced algorithms and machine learning models analyze historical and real-time data to predict potential failures, reduce downtime, and optimize maintenance schedules. By implementing our solutions, railway operators can ensure safer, more reliable, and cost-effective operations.

Logistics and Intelligent Mobility

We specialize in simulating and optimizing complex logistics and mobility systems, using advanced technologies to boost efficiency, cut costs, and enhance service levels. Our expertise covers various aspects of logistics and mobility, ensuring comprehensive, tailored solutions for your specific needs.

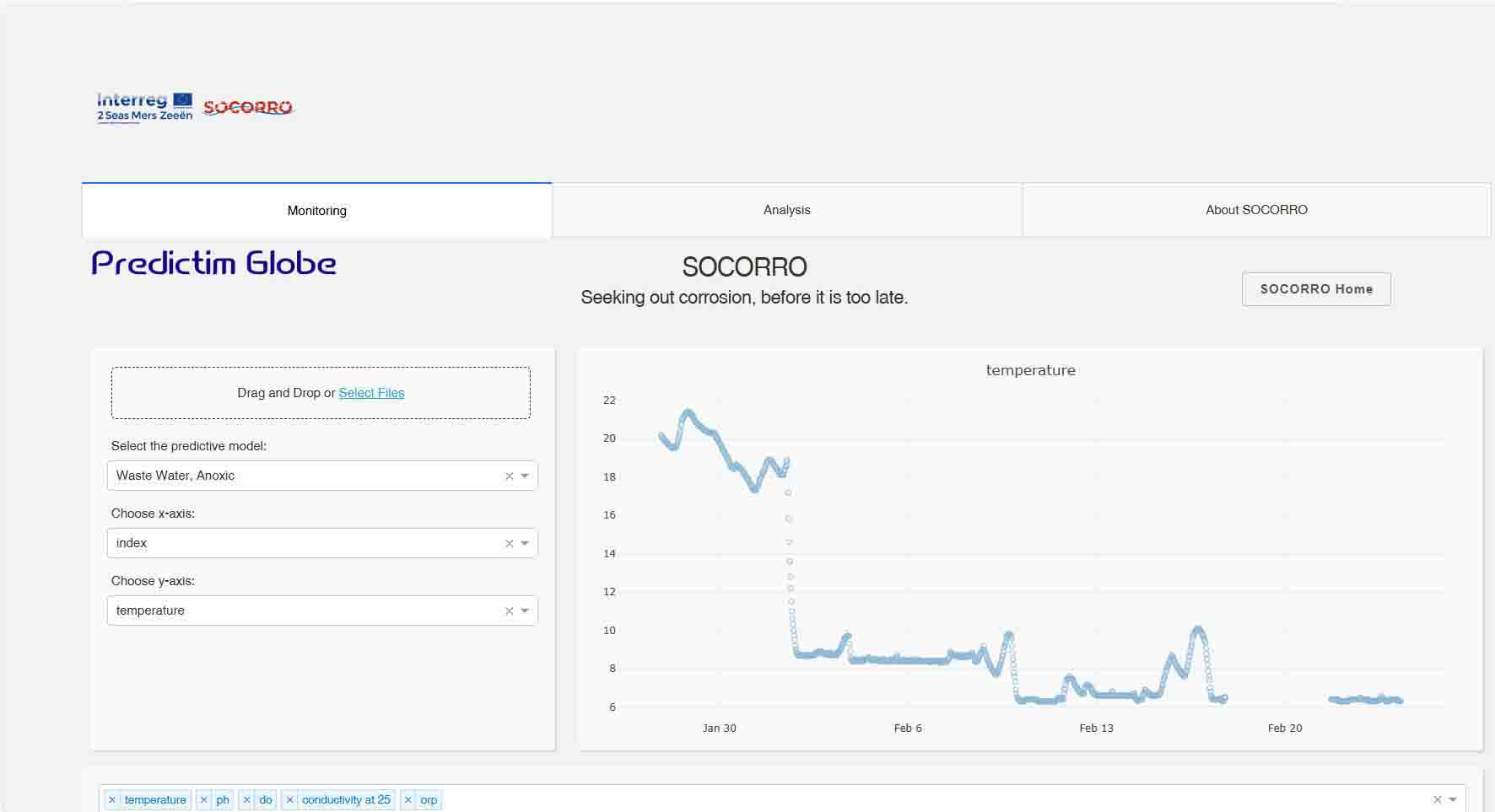

Corrosion Decision Support Systems

We provide innovative solutions to mitigate corrosion-related failures by identifying and assessing vulnerable infrastructure. Utilizing advanced AI techniques, mathematical models, and multimodal data, we help you plan maintenance interventions early, preventing major issues. This proactive approach reduces downtime and operational costs.

Port and Maritime Logistics

We specialize in simulating and optimizing complex maritime and port logistics systems, using cutting-edge technologies to boost efficiency, lower costs, and elevate service standards. Our expertise covers all aspects of maritime logistics, ensuring every solution is tailored to your unique operational challenges.

Intelligent Healthcare Logistics

We specialize in designing intelligent healthcare logistics optimization tools, using advanced technologies to boost efficiency, cut costs, and improve patient care. Our expertise covers all facets of healthcare logistics, ensuring each solution meets your specific operational needs.

Blog, News and Updates

Electrification and Sustainable Transportation: Toward a Greener Future

In an era defined by rapid technological change and escalating environmental challenges, the electrification of transportation stands at the forefront of the mobility revolution. As cities and nations strive to decarbonize and enhance efficiency, sustainable...

Navigating the Future: Trends Shaping Urban Mobility in the 21st Century

Urban mobility is undergoing a transformative evolution as cities strive to balance growth, sustainability, and technological innovation. For citizens, governments, and businesses alike, understanding these trends is essential to designing smarter, greener, and more...